Fitech Material(s), making the real difference

This product was successfully added to cart!

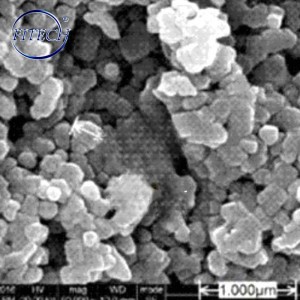

100nm/200nm/500nm Chromium Nitride Nanoparticles For Anticorrosive Coating

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd specializes in Nano Nitride more than 5 years, with rich experience, high quality, and competitive price. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy nano composites, metal nanoparticles, alloy nanoparticles, oxide nanoparticles, rare earth oxide nanoparticles, or look for price quotation, please contact judy@fitechem.com

Features

Nano chromium nitride, ultrafine chromium nitride powder prepared by variable current laser ion beam gas phase method, the powder particle size is small, uniform, high surface activity, sodium chloride-type structure, density 6.1g/cm3, stable to water, acid, alkaline. Nano chromium nitride is an excellent steel alloy additive; at the same time, due to its good physical and mechanical properties, it has better wear resistance than titanium nitride, and it is an anti-ferromagnetic material in nitride, which has a wide range of application prospects.

Chromium nitride, chemical formula CrN. Grayish-brown powder, density 6.1 g/cm ³, melting point 1770 degrees. Stable to water, acid, base. Chromium (III) compounds are on the list of Class 3 carcinogens.

Specification

| Type | Model | APS(nm) | Purity(%) | SSA(m2/g) | Density(g/cm3) | Crystal form | Color |

| Nano- | ZY-CrN-001 | 100 | >99.0 | 33.2 | 3.19 | cube | greyish black |

| Sub-micron | ZY-CrN-002 | 800 | >99.1 | 9.23 | 4.60 | cube | Grey-brown |

Applications

Chromium nitride is not only an excellent additive for steelmaking alloys, but also has good physical and mechanical properties, better than titanium nitride wear resistance. With high hardness and good wear resistance, it is mainly used for wear-resistant coating, can be used for corrosion-resistant metal coating materials and plastic molds, and is also used for multi-component coating materials. The chromic nitride film prepared by hollow cathode ion plating has Cr+Cr2N two-phase structure, the Chemicalbook grain size is 20 ~ 70nm, and the hardness is HV22GPa. After vacuum annealing, it can increase to HV35.4GPa, and its wear resistance is better than CrC film. Cr+Cr2N or single-phase CrN can be obtained from Cr+Cr2N film by reactive sputtering, and its hardness is HV20 ~ 25GPa(block CrN hardness HV11GPa), which is used as a wear-resistant coating.

Storage conditions

This product should be stored in dry, cool and sealing of the environment, can not be exposure to air, in addition should avoid the heavy pressure, according to ordinary goods transportation.

Exhibition Show

Factory & Payment

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.