Fitech Material(s), making the real difference

This product was successfully added to cart!

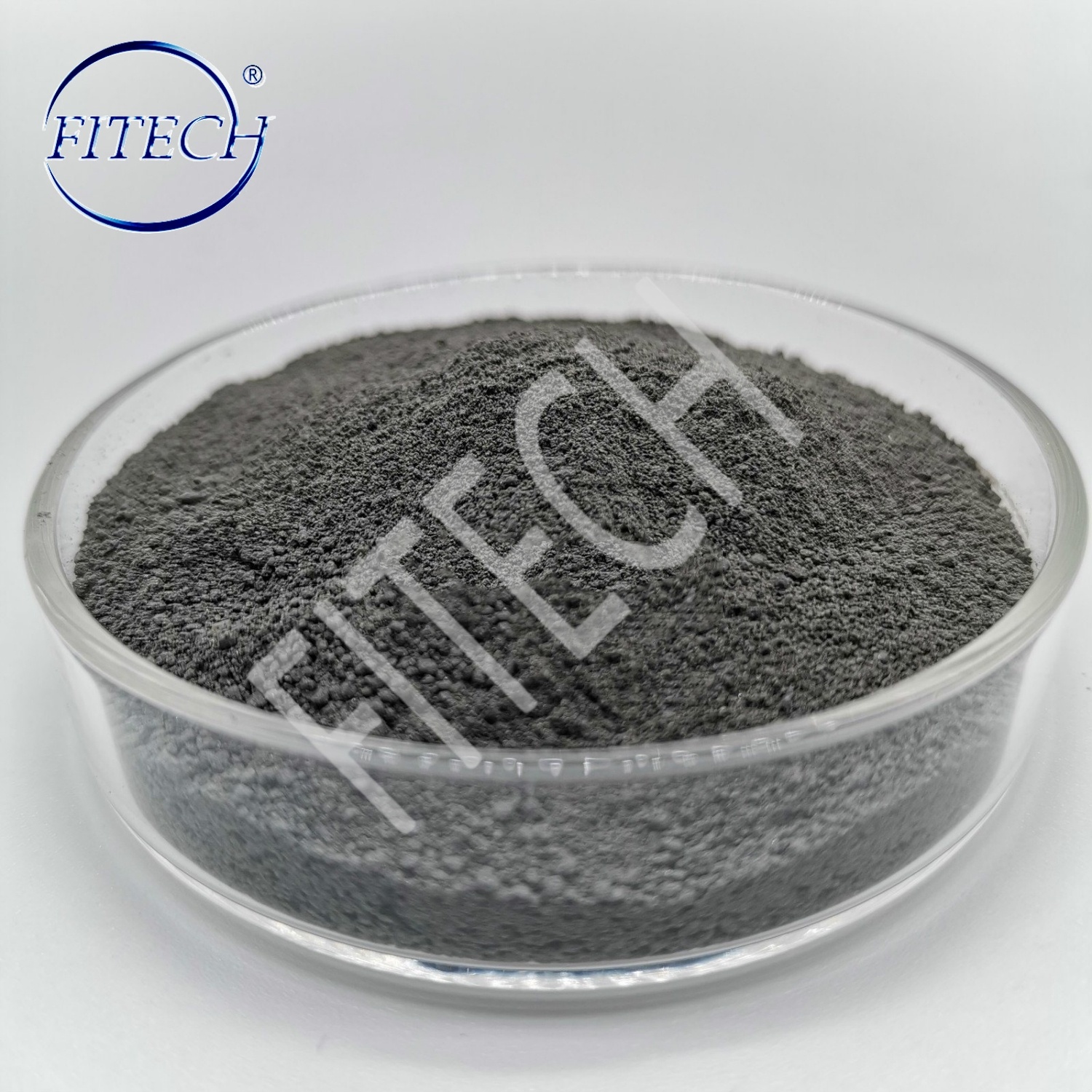

3D Printing 15-53μ M AISi7Mg Alloy Powder

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd has successfully certified by ISO 14001:2015 environmental management system,ISO 9001:2015 quality management system and ISO 45001 occupational health and safety certification. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy Cobalt base alloy powder, Nickel base alloy powder, Ferro base alloy powder, Titanium base alloy powder, other 3D printing powder, or look for price quotation, please contact judy@fitechem.com

Features

Aluminum alloy density is low, but the strength is relatively high, close to or more than high-quality steel, good plasticity, can be processed into various profiles, with excellent electrical conductivity, thermal conductivity and corrosion resistance, widely used in industry, the use of second only to steel.

High Sphericity & High Flowability.

Low Oxygen Content.The oxygen content is 300~800PPM.

Narrow Particle Size Distribution.

| Main products | AISi7Mg | |||

| Mobility | 15-53μm | ≤80s/50g | ||

| Bulk density | ≥1.35g/cm3 | |||

| Oxygen content | ≤300ppm | |||

| Nitrogen content | ≤200ppm | |||

| Mechanical property | Compressive strength / Mpa 460±20

Yield strength / Mpa 260±20 Elongation / % 8±2 |

|||

Applications

Aerospace

Aluminum alloy is the most widely used non-ferrous structural materials in the industry, and has been widely used in aviation, aerospace, automotive, machinery manufacturing, shipbuilding and chemical industries. With the rapid development of industrial economy, the demand for aluminum alloy welded structural parts is increasing day by day, which makes the weldability research of aluminum alloy further.

Aluminum alloy pressure processing products are divided into seven categories, such as rust prevention (LF), hard (LY), forging (LD), super hard (LC), coating (LB), special (LT) and brazing (LQ). Commonly used aluminum alloy materials for annealing (M stew), hardening (Y), hot rolling (R) and other three.

A N H U I F I T E C H M A T E R I A L C O . , L T D

National Innovation Industrial Base Huguang Road, Shushan District, Hefei, Anhui, China

Exhibition Show

Factory & Payment

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.