Fitech Material(s), making the real difference

This product was successfully added to cart!

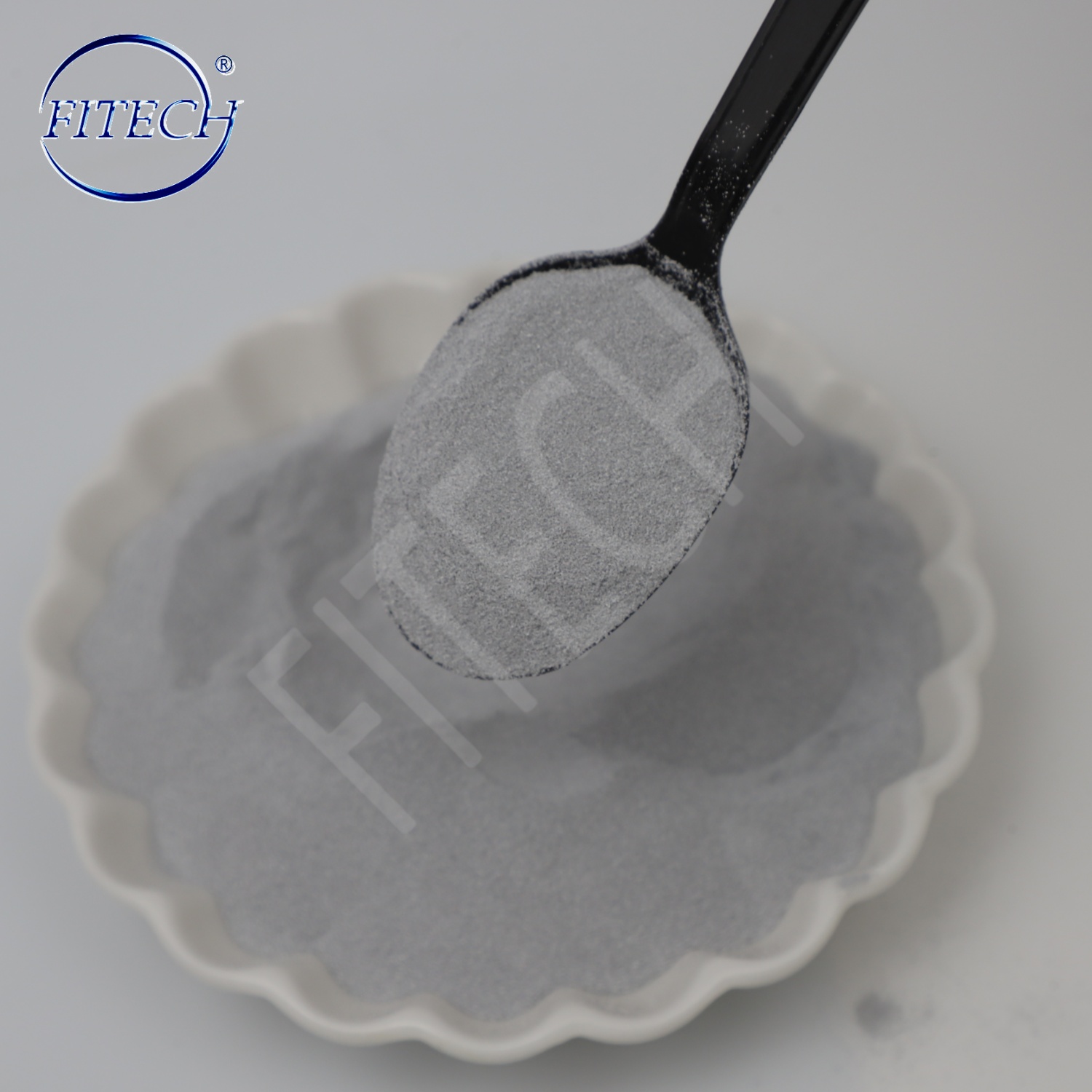

3D Printing Powder M4 Ferro-Based Alloy Powder High Vanadium High-Speed Steel

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd has successfully certified by ISO 14001:2015 environmental management system,ISO 9001:2015 quality management system and ISO 45001 occupational health and safety certification. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy Cobalt base alloy powder, Nickel base alloy powder, Ferro base alloy powder, Titanium base alloy powder, other 3D printing powder, or look for price quotation, please contact judy@fitechem.com

Features

1. High hardness: M4 high-speed steel has excellent hardness and can maintain high cutting performance under high-speed cutting conditions.

2. Good wear resistance: M4 high-speed steel has good wear resistance and can maintain a long service life during the cutting process.

3. Excellent thermal stability: M4 high-speed steel can still maintain high hardness and cutting performance under high temperature conditions, and is suitable for high-speed cutting.

| Items | Chemical Composition(wt%) | Remark | |||||||||

| Alloy | C | Si | Cr | Ni | Mn | Mo | Cu | W | V | Fe | |

| M4 | 1.25-1.40 | 0.2-0.45 | 3.75-4.5 | - | 0.15-0.4 | 4.5-5.5 | - | 5.25-6.75 | 3.75-4.5 | Bal. | - |

3D printing technology is a kind of rapid prototyping technology. It is a digital model file based on the use of metal powder, through the way of printing layer by layer to construct the object technology. In recent years, with the rapid development of 3D printing equipment, 3D printing has been widely used in mold manufacturing, automotive, aerospace, dentistry, medical education and other industrial fields.

Applications

1.Tool manufacturing: M4 metal powder is often used to manufacture various cutting tools, such as planers, turning tools, milling cutters, etc., which can maintain stable cutting performance under high-speed cutting conditions.

2. Drill bit manufacturing: Because M4 high-speed steel has high hardness and wear resistance, it is suitable for manufacturing various drill bits, such as center drills, thread drills, etc., and can maintain a long service life during the drilling process.

3. Tool coating: M4 metal powder can also be used to prepare tool coatings to improve the wear resistance and cutting performance of tools through surface spraying and other processes. In general, M4 metal powder is suitable for manufacturing various cutting tools due to its high hardness, wear resistance and thermal stability, and is widely used in metal processing, machinery manufacturing, aerospace and other fields.

| Particle Size | TappingDensity | Flowability | Particle Size Distribution (μm) | ||

| (g/cm³) | (s/50g) | D10 | D50 | D90 | |

| 15-45μm | 4.4-4.9 | ≤30 | 17-22 | 30-34 | 48-55 |

| 15-53μm | 4.4-4.9 | ≤30 | 20-25 | 32-37 | 51-61 |

A N H U I F I T E C H M A T E R I A L C O . , L T D

National Innovation Industrial Base Huguang Road, Shushan District, Hefei, Anhui, China

Exhibition Show

Factory & Payment

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.