Fitech Material(s), making the real difference

This product was successfully added to cart!

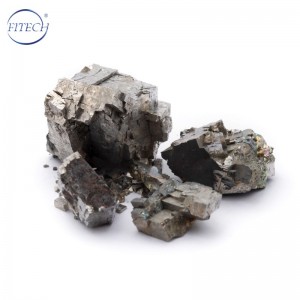

50%/80%Min 10~60mm Ferro Vanadium

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd specializes in Metal, alloy more than 10 years, with rich experience, high quality, and competitive price. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy Non-ferrous, Metallurgy, Chemical Raw Materials or look for price quotation, please contact info@fitechem.com

Specification (% )

Basic information:

Ferro vanadium is a kind of ferro alloy, which can be obtained by reducing vanadium pentoxide in an electric furnace with carbon, or by reducing vanadium pentoxide by the electric furnace si-thermo method. It is widely used as an element admixture in the smelting of vanadium alloy steel and alloy cast iron and, in recent years, in the manufacture of permanent magnets.

| Product name | Ferro Vanadium |

| Brand name | FITECH |

| CAS No | 12604-58-9 |

| Appearance | Metal Lump |

| MF | FeV |

| Size | 10~60mm |

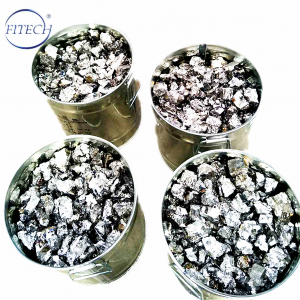

| Packing | 100/250kg iron drum |

Functions and Applications

Application:

Mainly used for smelting alloy steel. About 90% of the world's consumption of vanadium is used in the steel industry. Vanadium in ordinary low alloy steel is mainly used to refine grain, increase steel strength and restrain its aging effect. In alloy structural steel, it refines grain and increases strength and toughness of steel. It can be used in spring steel with chromium or manganese to increase the elastic limit of steel and improve its quality. It mainly refines the structure and grain of tool steel, increases its tempering stability, enhances its second hardening effect, improves its wear resistance and extends the service life of tool steel. Vanadium also plays a beneficial role in heat resistant steel and hydrogen resistant steel. The addition of vanadium in cast iron promotes the formation of pearlite due to the formation of carbides, which makes the cementite stable, the shape of the graphite particles fine and uniform, refining the grains of the matrix, thus improving the hardness, tensile strength and wear resistance of the casting.

Exhibition Show

Packing & Transportation

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.