Fitech Material(s), making the real difference

This product was successfully added to cart!

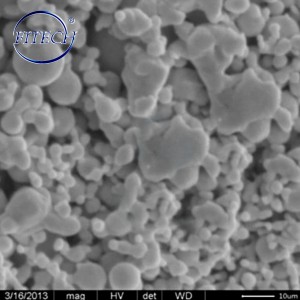

99.9% 3-5μm Metallurgy and Lubrication addition of High purity metal Tin powder

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd specializes in Nano metal more than 10 years, with rich experience, high quality, and competitive price. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy Tin Nanopowder or look for price quotation, please contact judy@fitechem.com

Features

Nanometer tin powder prepared by evaporation and condensation method, high sphericity, high purity, small particle size, uniform distribution, large specific surface area, small loose density, good dispersion, high oxidation temperature, good sintering shrinkage, is widely used in metal superhard materials as a fine grain, dispersion strengthening effect, improve the wear resistance and toughness of materials.

Specification

| Model | APS(nm) | Purity(%) | SSA(m2/g) | Volumn Density (g/cm3) | Density(g/cm3) | Crystal Form | Color |

| ZY-Sn001 | 50 | >99.9 | 27.5 | 0.4 | 5.7 | spherical | grey |

| ZY-Sn002 | 500 | >99.9 | 15 | 1.2 | 5.7 | spherical | grey |

| ZY-Sn003 | 1000 | >99.9 | 8 | 1.5 | 5.7 | subspherical | grey |

Applications

1. Micro and nano tin powder as a metal nano-lubricating additive: Add 0.1~0.5% nanometer tin powder to lubricating oil and grease to form self-lubricating and self-healing film on the surface of friction pair during friction process, which significantly reduces the anti-wear and anti-friction performance of friction pair;

2. Micro-nano tin powder as an active sintering additive: micro-nano tin powder greatly reduces the sintering temperature of non-metallurgical powder products and high temperature ceramic products in non-metallurgical powder;

3. Micro and nano tin solder: instead of micron tin powder to prepare high-performance welding and packaging alloy materials, used to improve welding performance and reduce welding temperature;

4. Metal and non-metal surface conductive coating treatment: in the absence of oxygen, the temperature below the melting point of the powder coating, this technology can be used for the production of microelectronic devices.

Storage Condition

This product is packed with inert plastic bags, sealed and stored in dry and cool environment, should not be exposed to air, prevent moisture oxidation and agglomeration, affect the dispersion performance and use effect; The quantity of packaging can be provided according to customer's request, sub-packaging.

Exhibition Show

Factory & Payment

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.