Fitech Material(s), making the real difference

This product was successfully added to cart!

99.99% Nano Alumina Powder Aluminium Oxide Al2O3 Alumina Nanoparticles Price for Ceramic

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd specializes in Nano Oxide more than 10 years, with rich experience, high quality, and competitive price. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy nano composites, metal nanoparticles, alloy nanoparticles, oxide nanoparticles, rare earth oxide nanoparticles, or look for price quotation, please contact judy@fitechem.com

Features

Alumina polishing powder is white and high purity powder. Calcination by tunnel kiln 1450 degrees high temperature, cutting force and gloss are excellent, with strong cutting force and high gloss. Molecular formula: AI2O3, molecular weight 102, melting point: 2050℃, boiling point: 2890℃, with high activity, non-toxic and tasteless, insoluble in water and insoluble in acid and base.

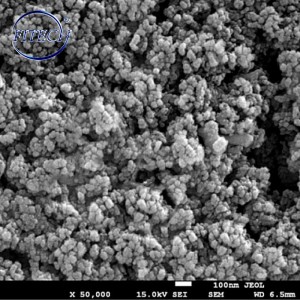

1, stable crystal phase, high hardness, small particles and uniform distribution;

2, strong grinding force, polishing fast, bright light, good mirror effect;

3, high grinding efficiency, good polishing effect, high surface finish, strong cutting force, fast light, can throw uniform and bright Xing Ze.

4, does not affect the color of the workpiece

5, can be used in the process of strictly prohibited iron powder residue to sandblast

6, micro powder grade is very suitable for wet sandblasting and grinding and polishing operations

7, processing speed, high quality

8, the amount of iron oxide is very low, it is very suitable for sandblasting operations that prohibit iron residue

9, after pickling step to remove impurities, high purity of alumina

Specification

|

Model |

APS(nm) |

Purity(%) |

Specific surface area(m2/g) |

Volume density(g/cm3) |

Density(g/cm3) |

Crystal form |

Color |

|

ZY-O-005-1 |

30 |

>99.99 |

160 |

0.916 |

3.91 |

γ |

white |

|

ZY-O-005-2 |

60 |

>99.99 |

100 |

1.524 |

3.91 |

α |

white |

Applications

1: It can be used in various sandblasting and grinding and polishing operations

2: Glass or acrylic crafts to enhance the aesthetic processing

3: In the manufacturing process of TV fluorescent screen

4: Cutting sand blasting of silicon wafer

5: Clean sand blasting of tooth grinding

6: sand for precision casting

7: Additives for high-grade refractory materials and other ceramics

Storage conditions

This product should be stored in dry, cool and sealing of the environment, can not be exposure to air, in addition should avoid the heavy pressure, according to ordinary goods transportation.

Exhibition Show

Factory & Transportation

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.