Fitech Material(s), making the real difference

This product was successfully added to cart!

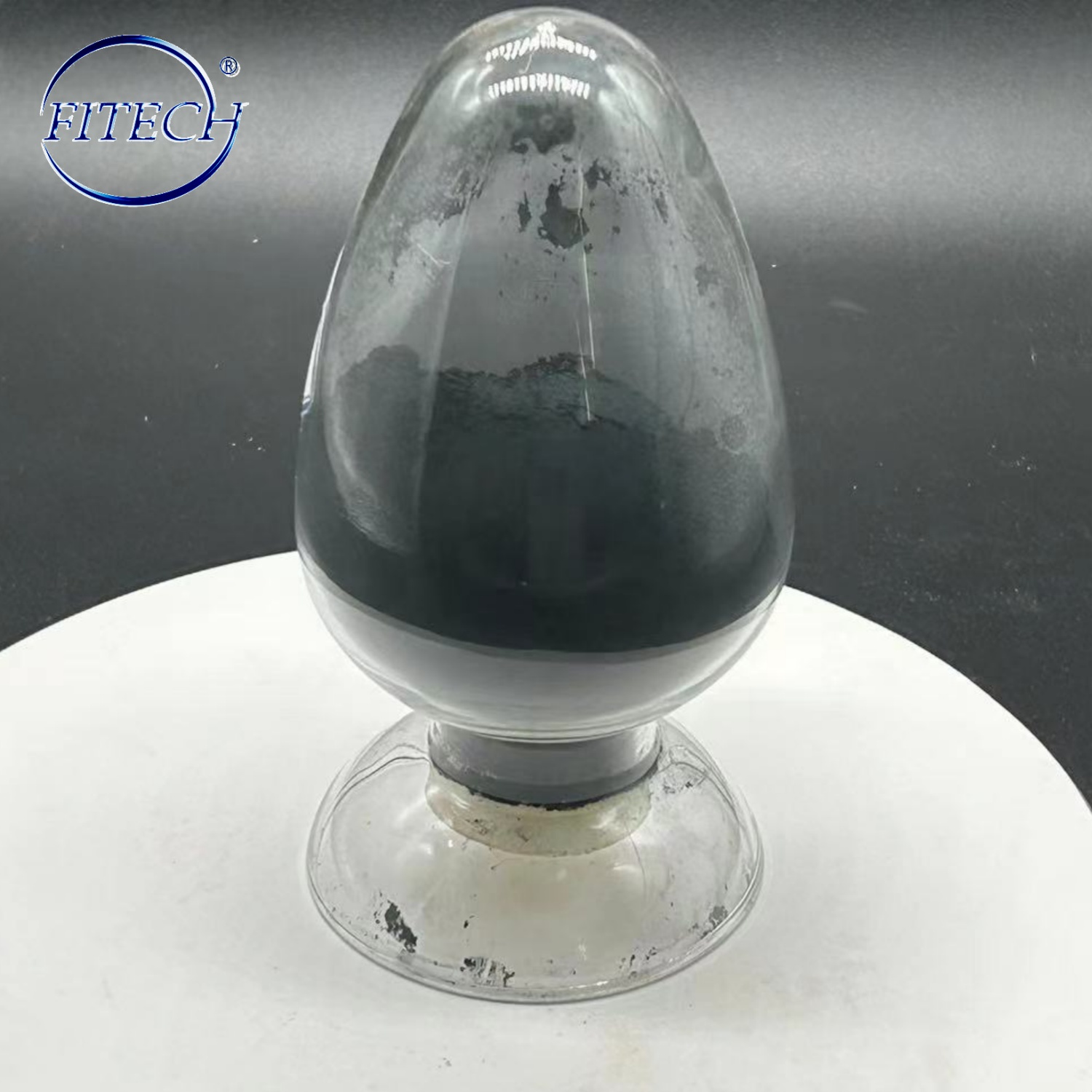

Anti-corrosion coating electric heating elements and high temperature structural materials MoSi2-200nm

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd specializes in Nano Silicide more than 3 years, with rich experience, high quality, and competitive price. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy nano composites, metal nanoparticles, alloy nanoparticles, oxide nanoparticles, rare earth oxide nanoparticles, or look for price quotation, please contact judy@fitechem.com

Features

Grayish black powder, density 6.28 g/cm ³, melting point 2030 degrees.

MoSi2 is a binary alloy of Mo-Si system containing high silicon content of an intermediate phase, with both metal and ceramic properties. MoSi2 is an intermediate phase with high silicon content in the Mo-Si binary alloy system, which has the dual characteristics of metal and ceramic. Molybdenum disilicide has good high-temperature oxidation resistance, high-temperature plasticity, thermal and electrical conductivity and fluidity, and has applications in the field of high-temperature structural ceramics.

Specification

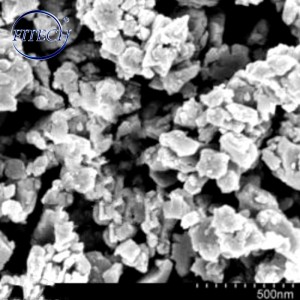

| Type | Model | APS(um) | Purity (%) |

SSA(m2/g) | Volume density(g/cm3) |

Crystal form |

Color |

| Sub-micron | ZY-MoSi2-001 | <1.0 | 99.5 | 24.24 | 4.21 | cube | black |

| Ultra fine | ZY-MoSi2-002 | 1-3um | 99.5 | 17.67 | 4.56 | cube | greyish black |

| Spray Grade | ZY-MoSi2-003 | 20-40 | 99.5 | 4.95 | 4.87 | sphere | greyish black |

Applications

1. Energy chemical industry: electric heating elements, high temperature heat exchangers for atomic reactor devices, gas burners, high temperature thermocouples and their protective tubes, melting vessels crucible.

2. Microelectronics industry: MoSi2 and some other refractory metal silicides Ti5Si3, WSi2, TaSi2 are important candidate materials for large-scale integrated circuit gate and interconnect films.

3. Aerospace industry: as a high temperature antioxidant coating material has been widely and deeply studied and applied. Especially as a turbine engine components, such as blades, impellers, burners, tail nozzle and sealing device materials.

4. Automotive industry: turbocharger rotor, valve body, spark plug and engine parts for automotive turbocharger.

Storage conditions

This product should be sealed and stored in a dry, cool environment, should not be exposed to the air for a long time, prevent moisture agglomeration, affecting the dispersion performance and use effect, should also avoid heavy pressure, do not contact with oxidants, according to the general cargo transport.

Exhibition Show

Factory & Payment

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.