Fitech Material(s), making the real difference

This product was successfully added to cart!

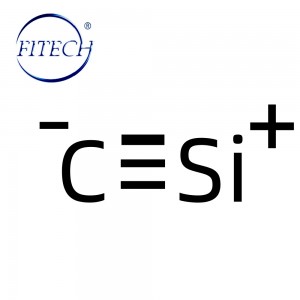

China Factory Directly Supply Powder Silicon Carbide Nano Silicon Carbide with 99% Purity

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd specializes in Nano Carbide more than 10 years, with rich experience, high quality, and competitive price. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy nano composites, metal nanoparticles, alloy nanoparticles, oxide nanoparticles, rare earth oxide nanoparticles, or look for price quotation, please contact judy@fitechem.com

Features

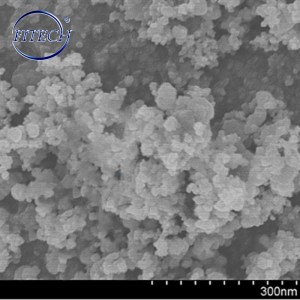

This product has high purity, small particle size distribution range, high specific surface area; It has the characteristics of stable chemical properties, high thermal conductivity, small thermal expansion coefficient, high hardness, wear resistance, etc. Nano silicon carbide has excellent thermal conductivity, is also a semiconductor, high temperature can resist oxidation.

Specification

| Item | Purity | APS | Color | Bulk Density | Morphology | oxygen content | Making method | SSA |

|---|---|---|---|---|---|---|---|---|

| Silicon carbide nanopowder | 99.50% | 40nm | Grey Green | 0.05g/cm3 | cubic | 0.50% | Plasma CVD | 29㎡/g |

Applications

1, the use of abrasives; It is mainly used for grinding wheel, sandpaper, sand belt, whetstone, grinding block, grinding head, grinding paste and photovoltaic products in monocrystalline silicon, polysilicon and piezoelectric crystals in the electronics industry.

2, chemical use; It can be used as a deoxidizer for steelmaking and an improver for cast iron structure, and can be used as a raw material for the manufacture of silicon tetrachloride, which is the main raw material for the silicone resin industry.

3, used for wear-resistant, fire-resistant and corrosion-resistant materials; The use of silicon carbide has corrosion resistance, high temperature resistance, high strength, good thermal conductivity, impact resistance and other characteristics, silicon carbide on the one hand can be used in a variety of smelting furnace lining, high-temperature furnace components, silicon carbide plate, lining plate, support parts, saggar, silicon carbide crucible and so on.

4, can be used for non-ferrous metal smelting industry of high temperature indirect heating materials, such as vertical distillation furnace, rectification furnace tray, aluminum electrolytic tank, copper melting furnace lining, zinc powder furnace arc plate, thermocouple protection tube; Used for the production of wear-resistant, corrosion-resistant, high-temperature silicon carbide ceramic materials; It can also be made into rocket nozzles, gas turbine blades, etc. In addition, silicon carbide is also one of the ideal materials for highways, aviation airstrips and so on.

Storage Conditions

Damp reunion will affect its dispersion performance and using effects, therefore, this product should be sealed in vacuum and stored in cool and dry room and it should not be exposure to air. In addition, the product should be avoided under stress.

Exhibition Show

Factory & Payment

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.