Fitech Material(s), making the real difference

This product was successfully added to cart!

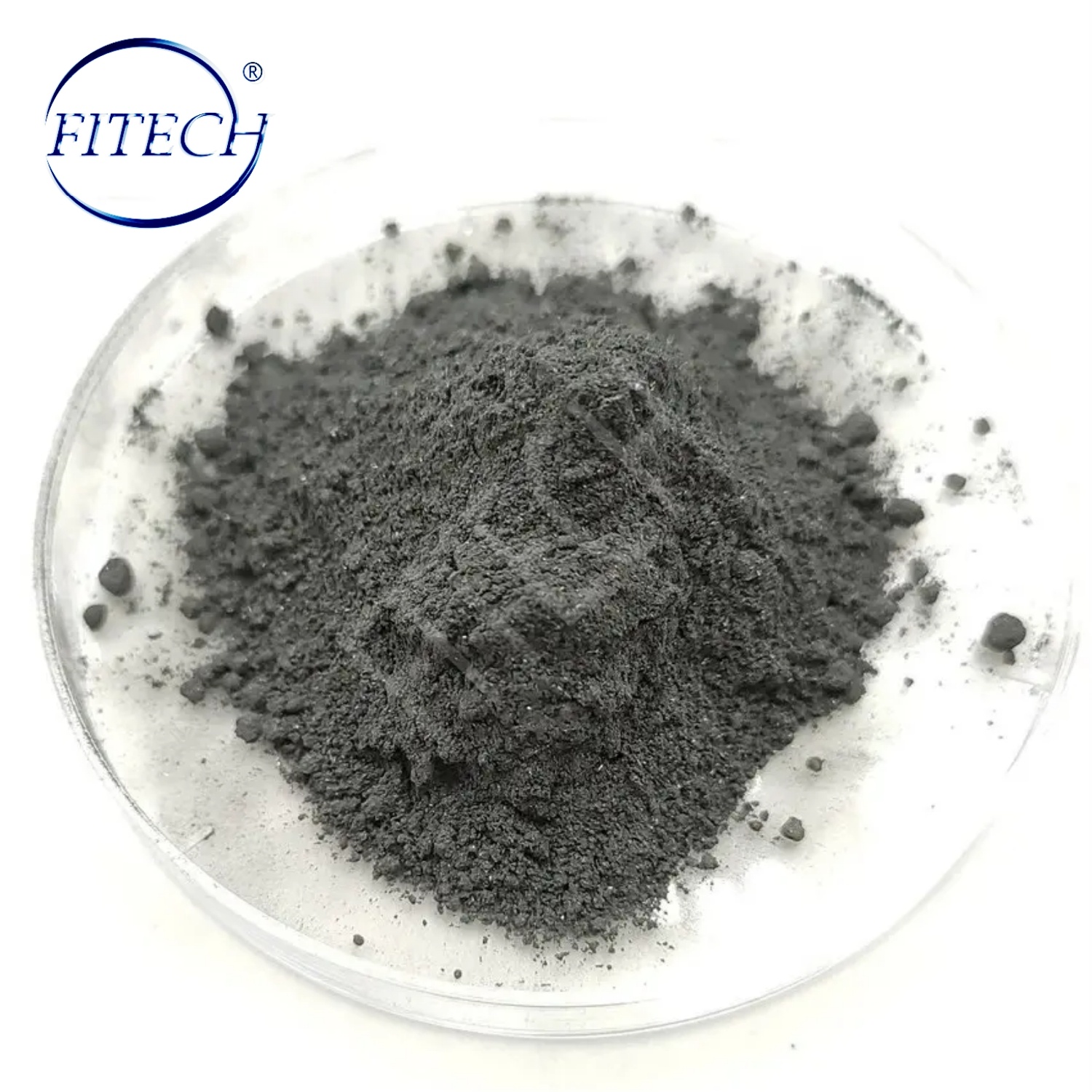

Chromium Carbide Powder (Cr2C) Sintered Chromium Carbide/Redox

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd has successfully certified by ISO 14001:2015 environmental management system,ISO 9001:2015 quality management system and ISO 45001 occupational health and safety certification. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy Chromium Carbide products, or look for price quotation, please contact judy@fitechem.com

Features

The production process consists of chromium and carbon carbonized in a vacuum. Its molecular formula is Cr7C3, its melting point is 1665 ° C (the theoretical weight of carbon is 10%), and its density is 6.9g/cm³. The melting point of Cr3C2 is 1890ºC (the theoretical weight of carbon is 13%), the density is 6.68g/cm³, the hardness is above HV2200, and the chromium carbide is non-toxic, non-corrosion, non-oxidation, tasteless. The appearance color of chromium carbide is silver gray. The lattice of chromium carbide is positive and negative, with a melting point of 1895 ° C and a boiling point of 3800 ° C. High wear resistance, corrosion resistance and high temperature resistance.

Specification

Metal chromium sintered chromium carbide

| Model | Chemical composition, % | ||||||

| Cr | C | Fe | Al | Si | P | S | |

| Cr2C | 88 ~ 91 | 9 ~ 11 | 0.50 | 0.30 | 0.30 | 0.02 | 0.03 |

| Cr3C2 | 84 ~ 87 | 12 ~ 14 | 0.50 | 0.30 | 0.30 | 0.02 | 0.03 |

| Cr7C3 | 75 ~ 81 | 17 ~ 24 | 1.0 | 0.30 | 0.30 | 0.02 | 0.03 |

Reduction of chromium carbide by chromium oxide

| Particle Size | Chemical compositon, % | ||||||

| Cr | C | Fe | Al | Si | 0 | N | |

| 1.5-2.5um | >85.5 | 13~ 14 | ≤0.1 | ≤0.02 | ≤0.05 | ≤0.6 | ≤0.1 |

| 4-6um | >85.5 | 13~ 14 | 0.12 | 0.03 | 0.13 | 1.1 | 0.08 |

Applications

1, It is a high melting point material with good wear resistance, corrosion resistance and oxidation resistance in high temperature environment, carbide particles made of nickel-chromium alloy, using plasma spraying method, can be used as high temperature resistance, wear resistance, oxidation resistance and acid resistance coating, widely used in aircraft engines and petrochemical machinery devices, can greatly improve the life of machinery. It is also commonly used as a grain refiner of cemented carbide and other wear-resistant and corrosion-resistant components. Cermet based on Cr3C2 has excellent oxidation resistance at high temperature.

2, Used for chromium carbide ceramics. Coarse-grained chromium carbide is used as melt-blown material to form melt-blown film on the surface of metal and ceramic, giving the latter wear resistance, heat resistance, corrosion resistance and other properties, and is widely used in aircraft engines and petrochemical machinery devices to greatly improve the mechanical life. It is also used to spray semiconductor films.

A N H U I F I T E C H M A T E R I A L C O . , L T D

National Innovation Industrial Base Huguang Road, Shushan District, Hefei, Anhui, China

Exhibition Show

Factory & Payment

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.