Fitech Material(s), making the real difference

This product was successfully added to cart!

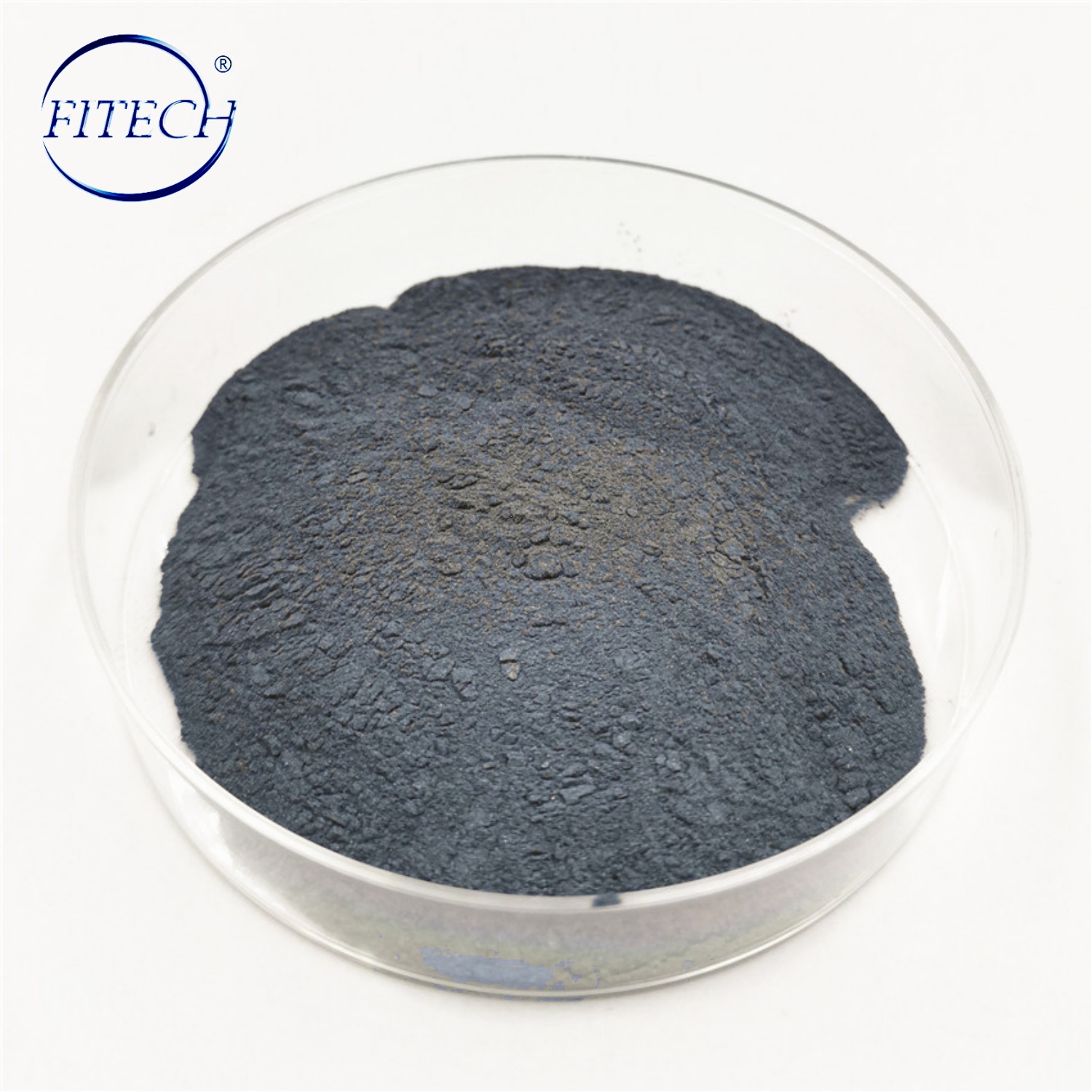

Cobalt-Based Alloy Cobalt Chromium Molybdenum Alloy for Medical Dental Model

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd has successfully certified by ISO 14001:2015 environmental management system,ISO 9001:2015 quality management system and ISO 45001 occupational health and safety certification. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy Cobalt base alloy powder, Nickel base alloy powder, Ferro base alloy powder, Titanium base alloy powder, other 3D printing powder, or look for price quotation, please contact judy@fitechem.com

Features

CoCrMo alloys are particularly susceptible to work hardening and cannot be manufactured in the same way as other metals, instead using vacuum precision casting. Controlling the mold temperature can control the grain size of the casting, and the formation of coarse grains at higher temperatures will reduce the strength, but it will also precipitate far away and larger carbides and reduce the brittleness of the material.

The elastic modulus of cobalt-based alloys does not change with the change of maximum tensile strength, and its value is in the range of 220 to 234 GPa, which is higher than other materials such as stainless steel.

| Main chemical composition | |

| Co:≥63 | Cr:26.5-30.0 |

| Mo:4.5-7.0 |

| main products | CoCrMo | |||

| mobility | 15-53μm | ≤20s/50g | ||

| Bulk density | ≥4.50/cm3 | |||

| oxygen content | ≤300ppm | |||

| nitrogen content | ≤300ppm | |||

| mechanical property | compressive strength /MPa 1000±50

yield strength /MPa 800±50 Elongation /% 30±2 |

|||

Applications

Cobalt-chromium-molybdenum alloy is based on cobalt as the main component, containing a considerable amount of chromium, molybdenum and a small amount of nickel, carbon and other alloying elements, and occasionally also contains iron alloys. Depending on the composition of the alloy, they can be made into welding wire, powder for hard surface surfacing, thermal spraying, spray welding and other processes.

Cobalt-chromium-molybdenum powder is commonly used to make dental restorative materials such as dentures and dental implants. This alloy has good biocompatibility, high strength and corrosion resistance and is suitable for use in the oral environment. It is usually used as a metal-based material for making cermet or all-porcelain restorations.

A N H U I F I T E C H M A T E R I A L C O . , L T D

National Innovation Industrial Base Huguang Road, Shushan District, Hefei, Anhui, China

Exhibition Show

Factory & Payment

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.