Fitech Material(s), making the real difference

This product was successfully added to cart!

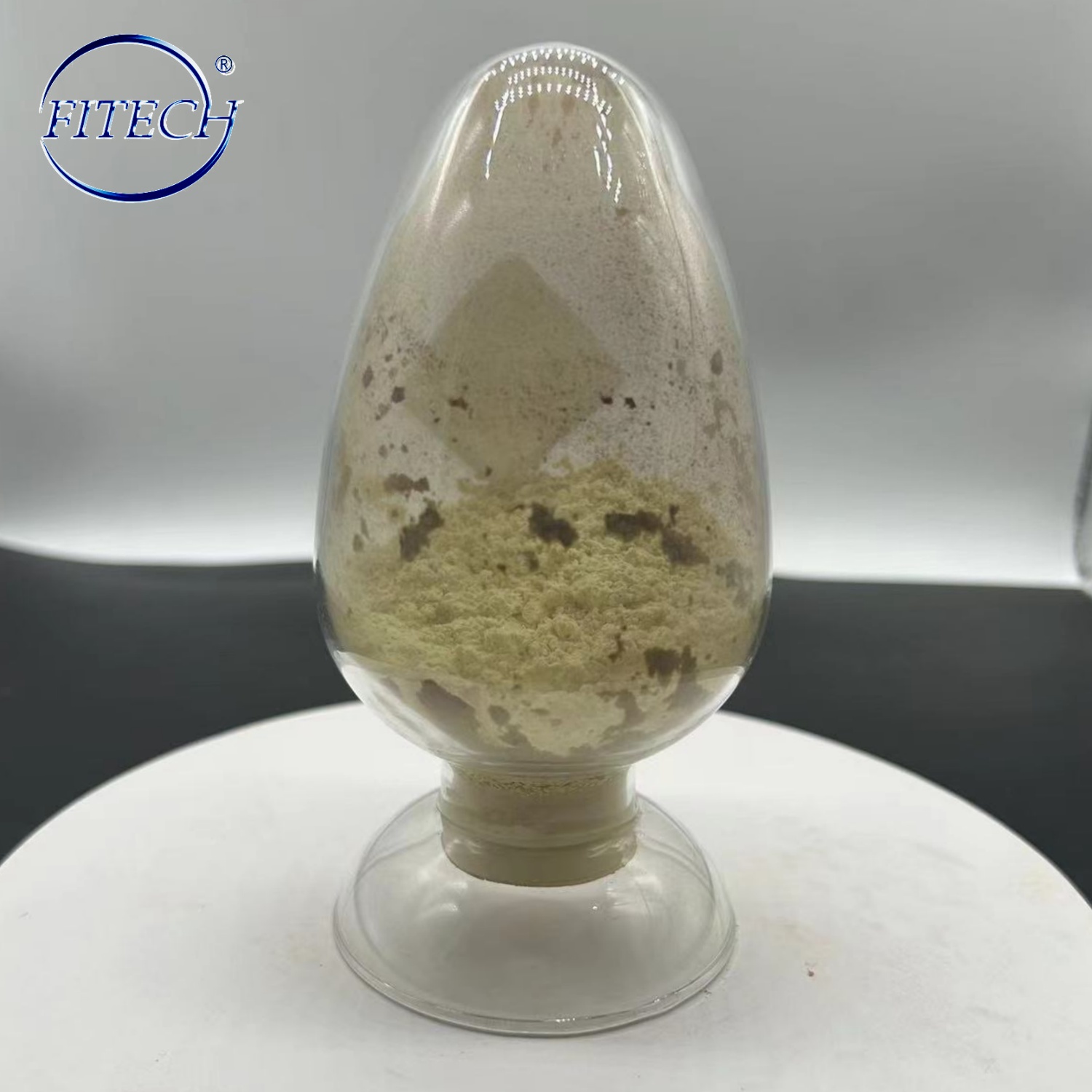

Heat stabilizer for silicone rubber with 99.99%Min 50nm Nano cerium dioxide

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd specializes in Cerium Oxide, Neodymium Oxide more than 10 years, with rich experience, high quality, and competitive price. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy Cerium Oxide or look for price quotation, please contact judy@fitechem.com

Features

Silicone rubber in the high temperature closed without oxygen state mainly occurs in the main chain thermal rearrangement degradation, that is, depolymerization reaction, so that the product becomes soft (or softened), resulting in the loss of mechanical strength, lose the use value. Under the conditions of high temperature aerobic environment, the oxidation of polymer side groups mainly occurs, forming alkyl radicals, and the coupling reaction of free radicals leads to an increase in the cross-chain density of the seal, which gradually hardens the product and even cracks (called hardening).

The addition of cerium oxide to silicone rubber can prevent the oxidative cross-linking of polysiloxane side chain and the cyclization of main chain. In a certain temperature range, it can prevent the free radical reaction caused by oxidation in silicone rubber, and can regenerate under the action of O2 in the air. By absorbing some trace acids or alkaline substances in the silicone rubber that can catalyze the degradation reaction, the silicone rubber plays a heat stabilization role.

At the same time, the special electronic structure of cerium oxide (f electron layer is not filled) makes it easy to form complexes, which inhibit the swelling of rubber in solvent by preventing the chain segment movement of rubber molecules, thus improving the oil resistance of rubber.

Specification

| Items | Index |

| Model | ZY-CeO205 |

| CeO2(w)% | 99.99 |

| APS(nm) | 50nm |

| SSA (m2/g) | 10-50 |

| Ln2O3 ≤ | 0.01 |

| Nd2O3+Pr6O11 ≤ | 0.03 |

| Fe2O3 ≤ | 0.01 |

| SiO2 ≤ | 0.02 |

| CaO ≤ | 0.01 |

| Al2O3 ≤ | 0.02 |

Applications

1, catalyst, polishing, chemical additives, electronic ceramics, structural ceramics, UV absorbent, battery materials

2, fine function ceramics; The addition to ceramics can lower the sintering temperature, inhibit the lattice growth, and improve the density of ceramics;

3, alloy coating: added in zinc nickel, zinc drill and zinc iron alloy to change the electrocrystallization process of zinc, promote the crystal surface to produce preferred orientation, the coating structure is more uniform, more dense, thereby improving the corrosion resistance of the coating;

4, polymer: can increase the thermal stability and aging resistance of the polymer.

5, used as plastic, rubber heat stabilizer and anti-aging agent

6, as a plastic lubricant, improve the lubrication coefficient of plastics,

7, used for polishing

Exhibition Show

Factory & Payment

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.