Fitech Material(s), making the real difference

This product was successfully added to cart!

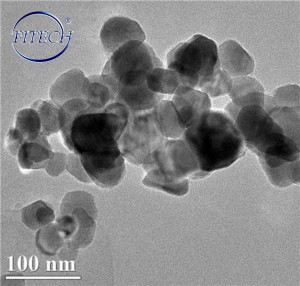

High Quality 100nm 99.99% Zincum Nanopowder

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd specializes in Nano Metal more than 10 years, with rich experience, high quality, and competitive price. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy nano composites, metal nanoparticles, alloy nanoparticles, oxide nanoparticles, rare earth oxide nanoparticles, or look for price quotation, please contact judy@fitechem.com

Features

Nanometer zinc powder and ultra-fine zinc powder were prepared by variable current laser ion beam gas phase method. The high active zinc powder has the characteristics of high content of metal zinc, low content of other impurity elements, smooth particle surface, large specific surface area, controllable average particle size, small loose pack density, less surface oxidation, less melting deformation and adhesion into grape-like particles, and is easy to disperse and industrial application.

Specification

| Item | Purity | APS | SSA | Color | Morphology | Bulk Density |

|---|---|---|---|---|---|---|

| Zn Nanoparticles | 99.99% | 60-80nm | 7 m2/g | purplish grey | Spherical | 0.85 g/cm3 |

Applications

Application

1, rubber field: in the rubber industry, nano-zinc is a vulcanizing active agent, excellent dispersion than ordinary zinc powder, can improve the thermal conductivity, wear resistance, tear resistance and other properties of rubber products, mainly used in natural rubber, styrene butadiene rubber, butadiene rubber, ethylene propylene rubber, butyl rubber and other rubber products, especially for nitrile butadiene rubber and PVC rubber foam industry performance is superior;

2, water-based inorganic zinc rich primer, inorganic zinc silicate workshop primer, inorganic zinc silicate anti-rust paint, epoxy zinc rich primer, fluorine carbon paint, etc.;

3, zinc anticorrosive coating production: the main use of anti-corrosion metal zinc for steel components, coating methods include hot plating, electroplating, thermal spraying, zinc-rich coating, powder plating, etc.

4. Chemical production: It is used in the production of insurance powder (sodium hyposulfate), Lide powder (zinc barium white), carving white block (sodium bisulfite formaldehyde), dye intermediates, etc., as a reducing agent with larger dosage and particle size than that of paint zinc powder, with an average particle size of 1μm;

5, ultrafine zinc powder is the main raw material for the manufacture of paint, coatings and chemical products such as carved white block, sodium zincate, zinc oxide, and organic synthesis of reducing agents;

6, in addition, nano-zinc powder, ultra-fine zinc powder is also widely used in metallurgical industry, battery industry, as well as pesticides, feed, dyes and manufacturing industry.

Storage Conditions

Damp reunion will affect its dispersion performance and using effects, therefore, this product should be sealed in vacuum and stored in cool and dry room and it should not be exposure to air. In addition, the Zinc Nanoparticles should be avoided under stress.

Cautions

Zn nanoparticle is flammable. It should be gently placed and avoided violent vibration and friction;

Zn Nanoparticle should be prevented from moisture, heat, impact and sunlight;

The user must be a professional (This person must know how to use Zinc Zn Nanoparticle.)

Exhibition Show

Packing & Transportation

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.