Fitech Material(s), making the real difference

This product was successfully added to cart!

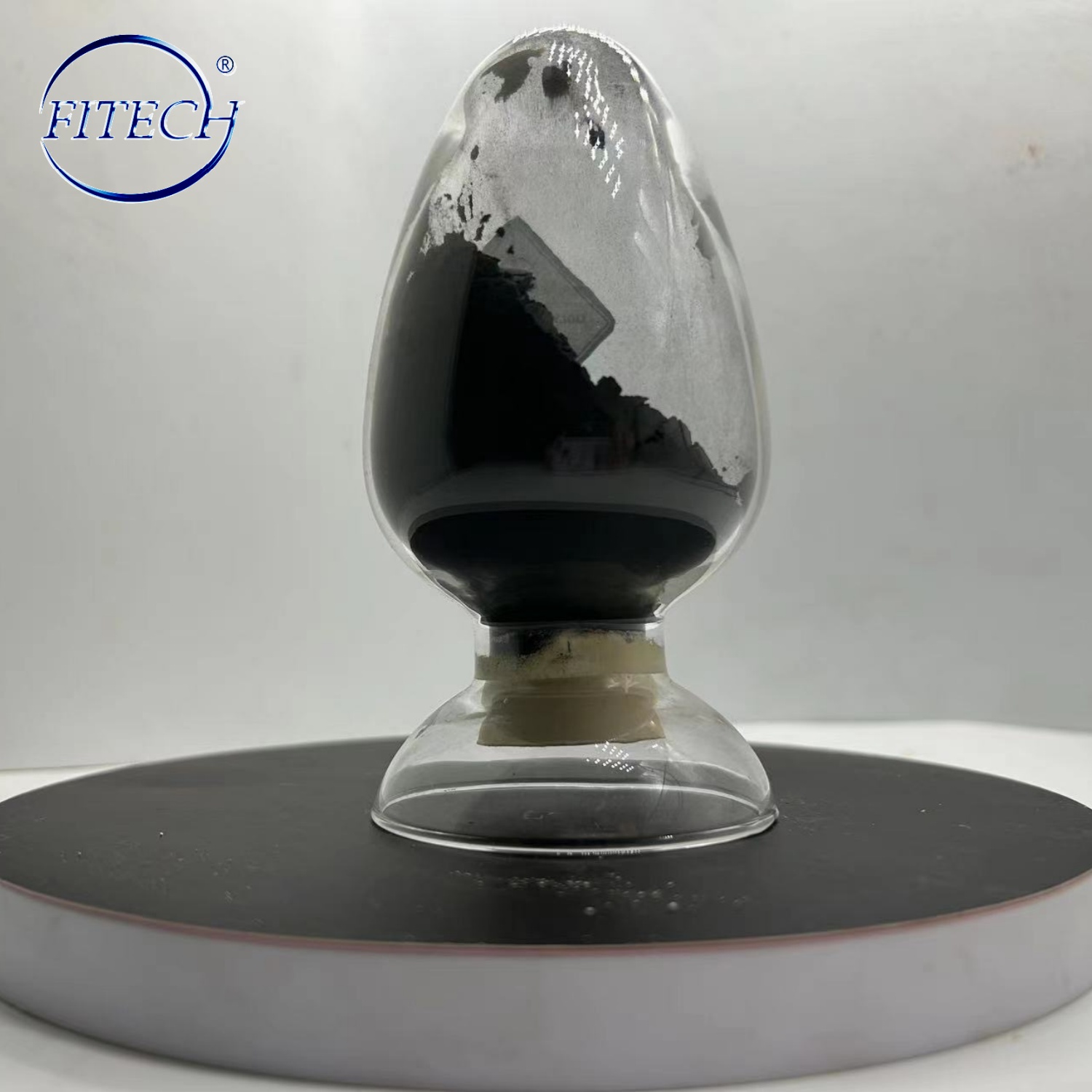

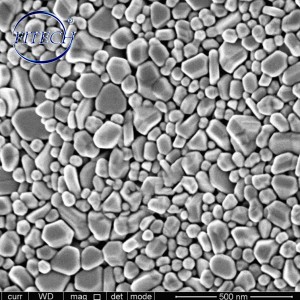

High Quality Nano Particle Size Material Ultrafine Spherical Lead Powder

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd specializes in Nano metal more than 10 years, with rich experience, high quality, and competitive price. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy Lead Nanopowder or look for price quotation, please contact judy@fitechem.com

Features

Lead powder, gray black powder, fine and greasy feeling heavy, insoluble in water and wine, soluble in carbonated water and dilute nitric acid. Melting point 327.5°C, boiling point 1740, density 11.3g/cm3 lead powder manufacturing methods there are two, one is to use a ball mill type of lead powder machine, lead in the machine is oxidized at the same time is ground, which is used in most countries. The second is the woman collapse method, which oxidizes the secondary lead in the European powder with the jet stream. Lead powder machine is generally a drum type, when it works, attached to the lead ball (block) in the drum, with the role of centrifugal force in the drum rotation, to a certain height, and then the use of gravity to fall, coupled with the high temperature and a certain humidity of the air in the cylinder, the surface of the lead, especially the edge of the deformation, by air oxidation, the formation of lead oxide. The lead oxide falls off the surface of the shot under the action of friction and impact force and is ground, so that lead powder can be obtained, and the lead powder is carried away by the air blown in. The size of the particles is related to the flow rate of the air.

Applications

1. For the manufacture of lead batteries Lead alloy can be used for type, do soldering; Lead is also used to make radioactive radiation, X-ray protective equipment and its compounds are more toxic to the human body, and can accumulate in the human body. Lead is used as a building material, in lead-acetate batteries, in bullets and artillery shells, and in welding, trophies, and some alloys.

2. Lead powder is used as a component of oil-free lubricant for powder metallurgy, and can be used for anti-corrosion coating when mixed with film forming substances

3. Lead powder is a special pigment used in Chinese painting. Now the general sale of tubes and pigment blocks, there are also pigment powder. Traditional Chinese painting pigments, which are generally divided into two categories of material and plant materials from the history of use, should first have minerals, after plants, just as ink first has pine smoke, after oil smoke. The bright color left on the ancient rock painting, according to the test, it was found that mineral pigments (such as cinnabar) were used, and the remarkable characteristics of mineral materials are not easy to fade and bright colors. Plant pigments are mainly extracted from trees and flowers. Lead powder is a mineral material.

Storage Condition

This product should be sealed and stored in a dry, cool environment, should not be exposed to the air for a long time, prevent moisture agglomeration, affecting the dispersion performance and use effect, and should avoid heavy pressure, do not contact with oxidants according to ordinary cargo transport.

Exhibition Show

Factory & Payment

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.