Fitech Material(s), making the real difference

This product was successfully added to cart!

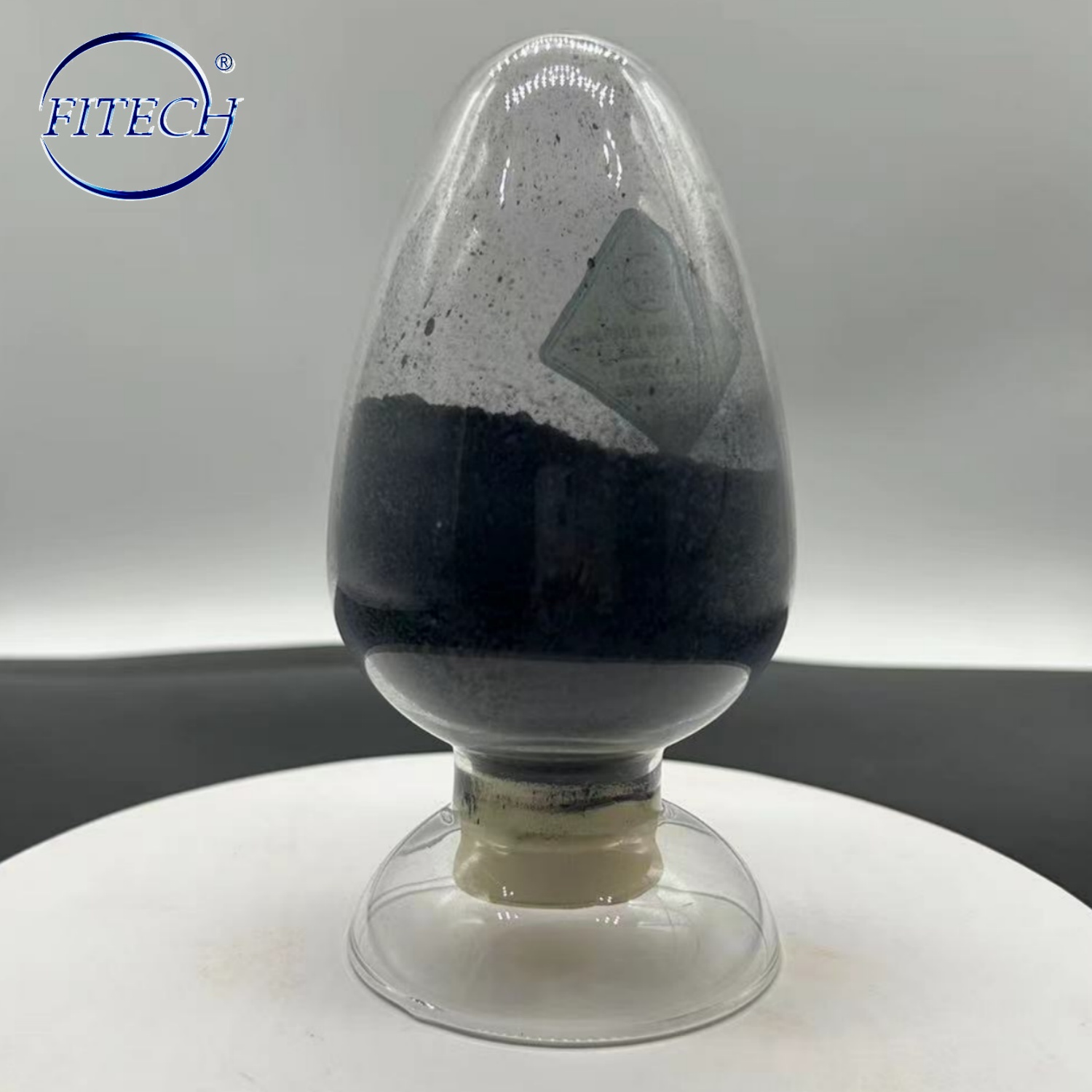

Layered molybdenum Disulfide Nanoparticles 99.9% For Lubricating Material

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd specializes in Nano Sulfide more than 3 years, with rich experience, high quality, and competitive price. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy nano composites, metal nanoparticles, alloy nanoparticles, oxide nanoparticles, rare earth oxide nanoparticles, or look for price quotation, please contact judy@fitechem.com

Features

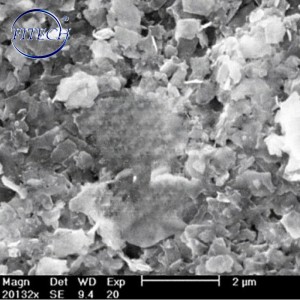

MoS2 nanoparticles, as a solid lubricant, one reason is of its layered structure, between layers of sulfur atoms combined with weak easy-to-slide and showed good friction-reducing effect; the second reason, exposure sulfur atoms of the crystal surface on the metal surface have a very strong adhesion to form a very solid film, therefore lubrication is superior to other general-lubricating materials. As compared with ordinary molybdenum disulfide, Nano molybdenum disulfide has many excellent properties, such as : excellent friction, large active surface area, more adsorption capacity, high reactivity, catalytic properties, especially the performance of catalytic hydrogenation desulfurization more, can be used to prepare special materials, catalytic materials and gas storage. In nano-layers of molybdenum disulfide into the other groups after the formation of intercalated nano-composite materials have many excellent physical properties (such as light, electricity, magnetism, catalysis, lubrication and other functions).

Specification

| Item | Purity | APS | Color | Bulk Density | Morphology | SSA |

|---|---|---|---|---|---|---|

| Molybdenum Disulfide Powder | 99.50% | 600-800nm | Dark Grey | 0.98g/cm3 | Sphere | 120㎡/g |

Applications

In lubricant applications: not only can improve the oil’s largest non-card bite load, but also can reduce wear and improve the friction properties, the mechanism for the average molybdenum disulfide is more prone to friction and chemical reaction than the nano molybdenum disulfide. The formation of sulfur and molybdenum-rich lubricating film, the sky antiwear. Molybdenum disulfide to reduce friction and wear mechanism is completely different from grease.High vacuum can continue to maintain its excellent resistance to friction and wear properties, its main application is for difficult to maintain equipment, such as: space vehicles, satellites and military fields.

In the composite application: PS/MoS2 nano composites, will have a certain conductivity of MoS2 as a conductive filler to improve the polystyrene (PS) of the electrical properties, it has a certain capacity but will not change the anti-static the insulation.

Storage Conditions

Damp reunion will affect its dispersion performance and using effects, therefore, this product should be sealed in vacuum and stored in cool and dry room and it should not be exposure to air. In addition, the product should be avoided under stress.

Exhibition Show

Factory & Payment

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.