Fitech Material(s), making the real difference

This product was successfully added to cart!

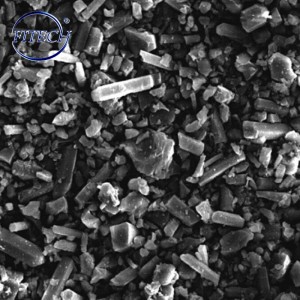

Nano-/ Micron- Silicon Nitride Whisker Many Kinds of Enhanced Composite Materials

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd specializes in Nano Nitride more than 5 years, with rich experience, high quality, and competitive price. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy nano composites, metal nanoparticles, alloy nanoparticles, oxide nanoparticles, rare earth oxide nanoparticles, or look for price quotation, please contact judy@fitechem.com

Features

Grayish white alpha crystal powder. Because it has a diamond type three-dimensional lattice structure, it has high temperature thermal stability, thermal shock resistance, chemical stability and good electrical insulation and hardness. Silicon nitride melting point 1900℃Chemicalbook, relative density 3.44. It is still stable when heated in the air to 1450 ~ 1550℃. Soluble in hydrofluoric acid, insoluble in cold, hot water and dilute acid, for concentrated sulfuric acid and concentrated sodium hydroxide solution is also very slow.

Specification

| Item | Purity | APS | SSA | Color | Crystal Formation | Morphology | Bulk Density |

|---|---|---|---|---|---|---|---|

| Si3N4 Nanoparticles | >99.9% | 20nm | 93m2/g | White | amorphous | spherical | 0.09g /cm3 |

| Si3N4 Nanoparticles | >99.9% | 800nm | 65m2/g | Grey White | Alpha | face-centered cubic | 0.23g /cm3 |

| Si3N4 Nanoparticles | >99.9% | 800nm | 49m2/g | Grey Light Green | Alpha | face-centered cubic | 0.69g /cm3 |

Applications

As engineering ceramic material, silicon nitride powder is widely used in industry. Mainly used in ultra-high temperature gas turbine, aircraft engine, turbine blade, heat exchanger, electric furnace and so on. It can also be used as a heat-resistant coating for rockets and nuclear reactors.

Mainly used as functional ceramic materials, non-ferrous metal fusible materials, aircraft engines, gas transmission nozzles, bearings and other high-temperature structural materials and heat-resistant coating and grinding, cutting, electric furnace and other materials.

Storage conditions

Damp reunion will affect its dispersion performance and using effects, therefore, this product should be sealed in vacuum and stored in cool and dry room and it should not be exposure to air. In addition, the product should be avoided under stress.

Exhibition Show

Factory & Payment

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.