Fitech Material(s), making the real difference

This product was successfully added to cart!

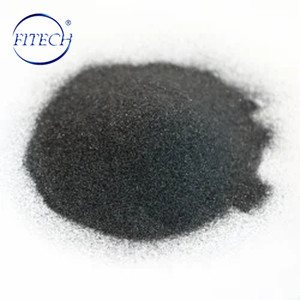

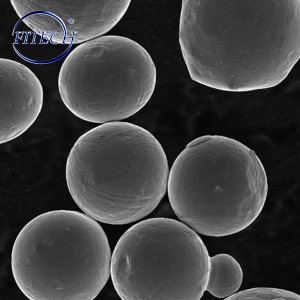

Nickel-Based Alloy Sperical Gh3625 Powder Inconel 625 in Laser Cladding

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd has successfully certified by ISO 14001:2015 environmental management system,ISO 9001:2015 quality management system and ISO 45001 occupational health and safety certification. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy Cobalt base alloy powder, Nickel base alloy powder, Ferro base alloy powder, Titanium base alloy powder, other 3D printing powder, or look for price quotation, please contact judy@fitechem.com

Features

GH3625(GH625) alloy is a solid solution strengthened nickel-based deformed superalloy with molybdenum and niobium as the main strengthening element. It has excellent corrosion resistance and oxidation resistance. It has good tensile and fatigue properties from low temperature to 980 degrees Celsius, and is resistant to stress corrosion under salt spray atmosphere.

| Main products | GH3625 | |||

| Mobility | 15-53μm | ≤18s/50g | ||

| Bulk density | ≥4.40g/cm3 | |||

| Oxygen content | ≤200ppm | |||

| Nitrogen content | ≤200ppm | |||

| Mechanical property | Compressive strength /Mpa 1000±70

Yield strength /Mpa 750±50 Elongation /% 35±5 |

|||

The chemical composition of the alloy is divided into three categories: standard components, high quality components, high purity components. High-quality components reduce carbon and increase niobium on the basis of standard components, thereby reducing the amount of niobium carbide, reducing the number of fatigue sources and strengthening phases, improving the content of fatigue resistance, and improving the purity and comprehensive performance of the material.

Applications

Aeroengine parts (guides, turbine blades, turbine discs, combustion chambers), aerospace structures, chemical equipment, waste disposal equipment, professional Marine equipment.

It can be widely used in the manufacture of aerospace engine components, aerospace structural components and chemical equipment.

Components of organic chemical processes containing chlorides, especially where acid chloride catalysts are used;

Digesters and bleaching tanks for the pulp and paper industry;

Absorption tower, reheater, flue gas inlet baffle, fan (wet), agitator, baffle and flue in flue gas desulfurization system;

For the manufacture of equipment and components for use in acidic gas environments;

Acetic acid and acetic anhydride reaction.

A N H U I F I T E C H M A T E R I A L C O . , L T D

National Innovation Industrial Base Huguang Road, Shushan District, Hefei, Anhui, China

Exhibition Show

Factory & Payment

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.