Fitech Material(s), making the real difference

This product was successfully added to cart!

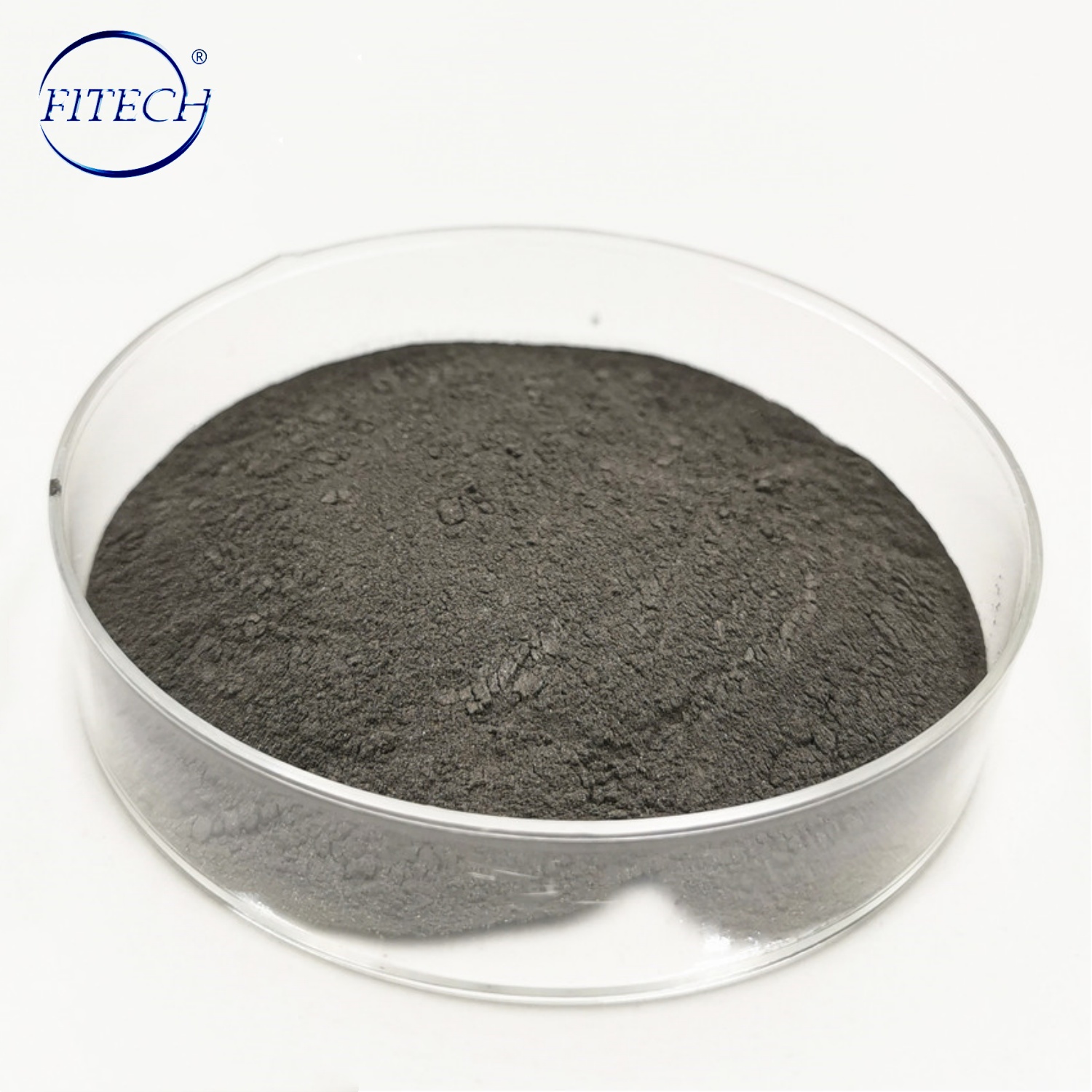

Non-Magnetic Nickel Free Austenitic Stainless Steel Powder 304L/316L/321/310S

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd has successfully certified by ISO 14001:2015 environmental management system,ISO 9001:2015 quality management system and ISO 45001 occupational health and safety certification. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy Cobalt base alloy powder, Nickel base alloy powder, Ferro base alloy powder, Titanium base alloy powder, other 3D printing powder, or look for price quotation, please contact judy@fitechem.com

Features

Austenitic stainless steel refers to stainless steel with austenitic structure at room temperature. When Cr is about 18%, Ni 8%-10% and C is about 0.1%, the steel has a stable austenitic structure. Austenitic chromium-nickel stainless steel includes the famous 18Cr-8Ni steel and the high Cr-Ni series steel developed on this basis by increasing the content of Cr and Ni and adding Mo, Cu, Si, Nb, Ti and other elements. Austenitic stainless steel is non-magnetic and has high toughness and plasticity, but the strength is low, it is impossible to strengthen it through phase change, and it can only be strengthened by cold working, such as adding S, Ca, Se, Te and other elements, it has good machinability.

Because austenitic stainless steel has good forming and corrosion resistance, it has been widely used in various fields including medical and personal wearable products. However, in recent years, it has been found in clinical use that nickel in stainless steel can cause human allergies and may induce other blood diseases. Therefore, the new high-nitrogen nickel-free stainless steel material came into being. The new medical stainless steel material using nitrogen instead of nickel not only avoids the potential harm of nickel, but also has excellent mechanical properties and biocompatibility.

| Norminal Composition(wt%) | |||||||||

| C | Cr | Mn | Mo | Ni | N | Si | Cu | O | Fe |

| <=0.08 | 17.5~19.5 | 14.0~16.0 | 2.0~4.0 | <=0.1 | 0.2~0.6 | <=1.0 | <=0.5 | <=0.12 | Bal. |

Applications

1. 304 stainless steel: often used in the production of kitchen utensils, food processing equipment, chemical containers, building decoration, etc.

2. 316 stainless steel: with higher corrosion resistance, often used in seawater environment, chemical equipment, medical equipment and so on.

3. 321 Stainless steel: with high temperature resistance, often used in heat exchangers, furnace tubes, chemical equipment and so on.

4. 310S stainless steel: Excellent high temperature resistance, often used in stoves, furnace tubes, heat treatment equipment, etc.

These austenitic stainless steel materials have a wide range of applications in industry, construction, chemical, medical and other fields. Different grades are suitable for different environmental and engineering requirements, and choosing the right stainless steel material can ensure that the product has good performance and durability.

| Particle Size | TappingDensity | Particle Size Distribution (μm) | ||

| (g/cm³) | D10 | D50 | D90 | |

| 15-53μm | 4.4-4.9 | 17-22 | 30-34 | 48-55 |

| 53-120μm | 4.5-4.8 | 49-56 | 70-78 | 96-110 |

| 53-150μm | 4.5-4.8 | 56-66 | 85-97 | 125-150 |

A N H U I F I T E C H M A T E R I A L C O . , L T D

National Innovation Industrial Base Huguang Road, Shushan District, Hefei, Anhui, China

Exhibition Show

Factory & Payment

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.