Fitech Material(s), making the real difference

This product was successfully added to cart!

Fatory supply Silicon Carbide Powder SiC Nanoparticles at Best Sale

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd specializes in Nano Materials more than 10 years, with rich experience, high quality, and competitive price. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy nano composites, metal nanoparticles, alloy nanoparticles, oxide nanoparticles, rare earth oxide nanoparticles, or look for price quotation, please contact judy@fitechem.com

Features

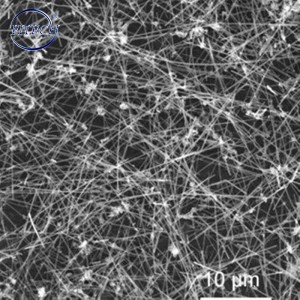

Silicon carbide nanoparticles possesses high purity, narrow range particle size distribution, and larger specific surface area;

Silicon carbide nano powder has chemical stability, high thermal conductivity, smaller thermal expansion coefficient and better abrasion resistance;

The micro hardness of SiC nanoparticles is 2840 ~ 3320kg/mm2 and hardness is between corundum and diamond; Its mechanical strength is higher than the corundum.

Inhalation of silicon carbide dust can deposit in the lungs, leading to lung disease. The substance may be harmful to the environment, and special attention should be paid to water bodies.

Specification

| Item | Purity | APS | Color | Bulk Density | Morphology | oxygen content | Making method | SSA |

|---|---|---|---|---|---|---|---|---|

| Silicon carbide nanopowder | 99.50% | 40nm | Grey Green | 0.05g/cm3 | cubic | 0.50% | Plasma CVD | 29㎡/g |

Applications

With its exceptional hardness and strength, this compound is perfect for cutting tools, grinding applications, and electrical components. Its outstanding thermal conductivity makes it a reliable choice for heat management solutions.

Elevate your projects with premium quality silicon carbide products! Known for their exceptional resistance to wear and corrosion, these materials are essential for manufacturing sealed bearings, mechanical seals, and ceramic cutting tools. Take advantage of silicon carbide's unique properties to achieve outstanding results in your applications.

Storage Conditions

Damp reunion will affect its dispersion performance and using effects, therefore, this product should be sealed in vacuum and stored in cool and dry room and it should not be exposure to air. In addition, the product should be avoided under stress.

A N H U I F I T E C H M A T E R I A L C O . , L T D

National Innovation Industrial Base Huguang Road, Shushan District, Hefei, Anhui, China

Exhibition Show

Factory & Payment

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.