Fitech Material(s), making the real difference

This product was successfully added to cart!

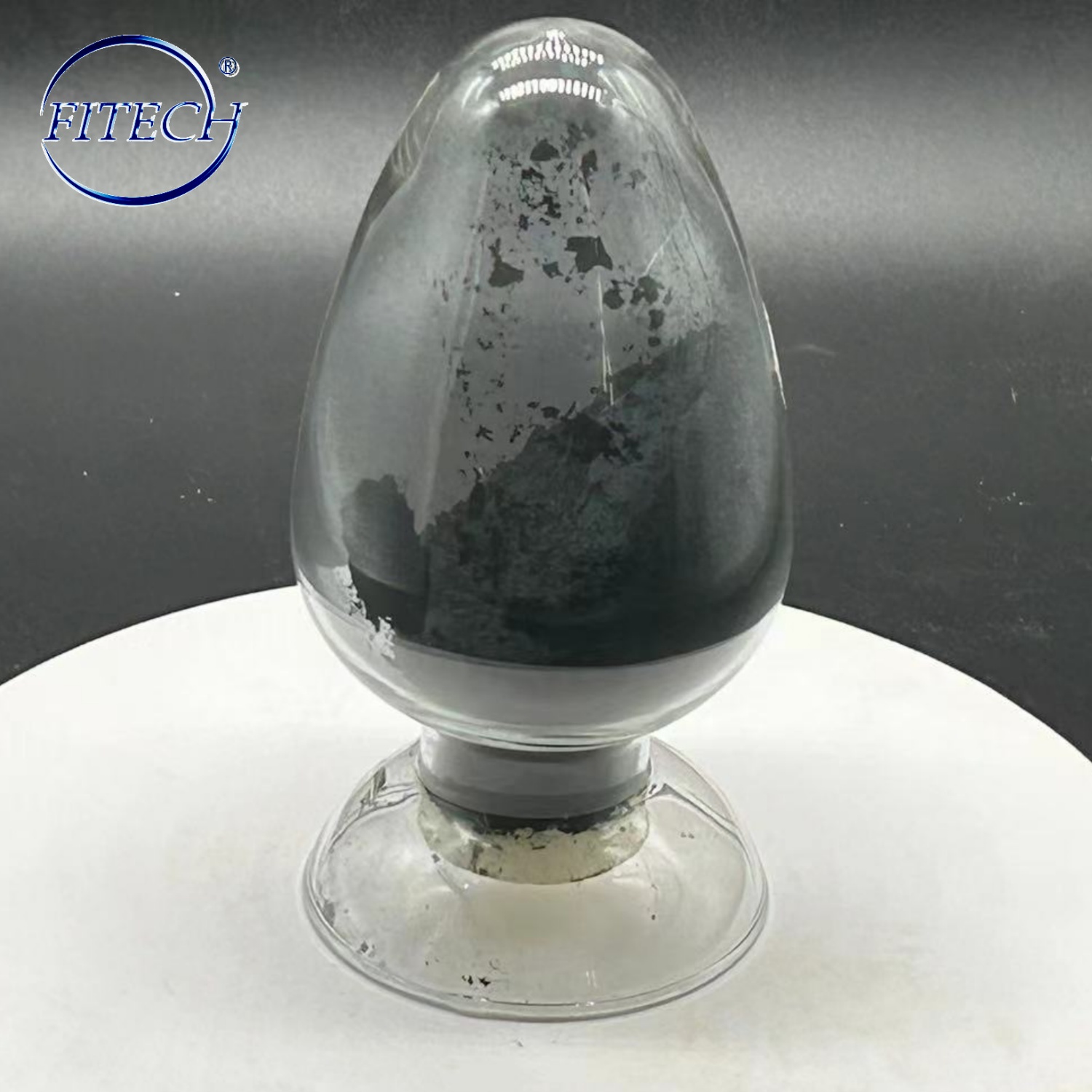

Sputtering Target Zirconium Diboride Nanoparticles with Favorable Price

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd specializes in Nano Boride more than 3 years, with rich experience, high quality, and competitive price. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy nano composites, metal nanoparticles, alloy nanoparticles, oxide nanoparticles, rare earth oxide nanoparticles, or look for price quotation, please contact judy@fitechem.com

Features

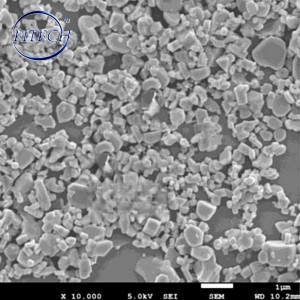

This product is gray crystal or powder, relative density 6.085, melting point 324.5℃. High temperature resistance, high strength at room temperature and high temperature. Good shock resistance, small resistance, high temperature oxidation resistance.

Zirconium boride powder has the advantages of low density, high melting point, high hardness, high specific strength, high specific stiffness, good thermal conductivity, excellent electrical conductivity, excellent ablative resistance and oxidation resistance.

Specification

|

Model |

APS(nm) |

Purity(%) |

Specific surface area(m2/g) |

Volume density(g/cm3) |

Density(g/cm3) |

Crystal form |

Color |

|

ZY-B-001 |

50 |

>99.9 |

45 |

0.489 |

1.23 |

hexagon |

black |

Note: according to user requirements of nano particle can provide different size products.

Applications

Zirconium boride ultra-high temperature ceramics have been widely used as a variety of high temperature structure and functional materials, such as: turbine blades in the aviation industry, magnetic fluid power generation electrodes. As a thermal insulation zirconium boride powder material, it is required to have excellent thermal shock resistance of Chemicalbook, but the existing zirconium boride powder can not meet the requirements. Compared with the ceramic material made of spherical particles, the ceramic material made of flake or rod-like powder has better heat shock resistance.

Zirconium boride powder has been widely used in aerospace, military manufacturing, metallurgical minerals and mechanical processing. At present, the main method of preparing zirconium boride ceramics is sintering zirconium boride Chemicalbook powder under high temperature and high pressure. Therefore, the preparation of zirconium boride powder with high purity and good sintering performance is the key to play its great application value.

Storage conditions

This product should be stored in dry, cool and sealing of the environment, can not be exposure to air, in addition should avoid the heavy pressure, according to ordinary goods transportation.

Exhibition Show

Factory & Payment

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.