Fitech Material(s), making the real difference

This product was successfully added to cart!

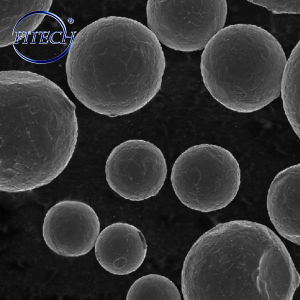

Stainless Steel H13 Ferro-Based Alloy Metal Powder

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd has successfully certified by ISO 14001:2015 environmental management system,ISO 9001:2015 quality management system and ISO 45001 occupational health and safety certification. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy Cobalt base alloy powder, Nickel base alloy powder, Ferro base alloy powder, Titanium base alloy powder, other 3D printing powder, or look for price quotation, please contact judy@fitechem.com

Features

H13 steel is the most widely used and most representative hot work die steel, its main characteristics are:

(1) With high hardenability and high toughness;

(2) Excellent thermal cracking resistance, which can be water-cooled in the workplace;

(3) has medium wear resistance, can also use carburizing or nitriding process to improve its surface hardness, but slightly to reduce the thermal cracking resistance;

(4) Due to its low carbon content, the secondary hardening ability in tempering is poor;

(5) It has the ability to resist softening at higher temperatures, but the hardness decreases rapidly when the temperature is higher than 540 ° C (1000 ° F) (that is, the working temperature of the ability is 540 ° C);

(6) Small deformation of heat treatment;

(7) Medium and high machinability;

(8) Medium resistance to decarbonization.

| Main chemical composition | Oxygen and nitrogen content/Mechanical properties (Heat treatment) | ||

| Fe:surplus | Cr:≤4.75-5.50 | Oxygen content:≤500ppm | Nitrogen content:≤70ppm |

| Mo:1.10-1.75 | V:0.8-1.2 | Hardness/HRC:52-58 | Compressive Strength /MPa:1880±10 |

| Mn:0.2-0.5 | Si:0.8-1.2 | Yield strength /MPa:1520±20 | Elongation /%:4±2 |

Applications

The use and 9CRWMN die steel are basically the same, but because of its higher vanadium content, the medium temperature (600 degrees) performance is better than 4Cr5MoSiV steel, which is a representative steel with a wide range of uses in hot work die steel.

H13 die steel is used to manufacture forging dies, hot extrusion dies and precision forging dies with large impact loads; Aluminum, copper and their alloys die casting.

H13 is a hot work die steel, which is formed by adding alloying elements on the basis of carbon steel, implementing the standard GB/T1299-2014. Unified digital code T23353; Grade 4Cr5MoSiV1. At medium temperature (~600°), the overall performance is good, the hardenability is high (can be hardened in the air), the heat treatment deformation rate is low, and the performance and service life are higher than 3Cr2W8V.

A N H U I F I T E C H M A T E R I A L C O . , L T D

National Innovation Industrial Base Huguang Road, Shushan District, Hefei, Anhui, China

Exhibition Show

Factory & Payment

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.